Ensuring the safety and freshness of packaged food products involves a crucial process called seal inspection. This procedure verifies that the seals on food packaging are intact and effective, preventing contamination and maintaining the product’s quality. This guide outlines the importance of seal inspection and provides a detailed approach to performing it effectively.

Understanding seal inspection

Seal inspection is an integral part of food packaging that helps ensure the safety, quality, and shelf life of the product. Many food items are packed in a controlled environment with gas mixtures to prevent contamination and preserve their original appearance, nutrients, taste, and shelf life. A proper seal ensures that external contaminants do not enter the package, thus keeping the food safe for consumption.

Why seal integrity matters

Maintaining seal integrity is essential for several reasons:

- Food safety: An intact seal prevents contaminants such as bacteria, dust, and other particles from entering the food package, thereby reducing the risk of foodborne illnesses.

- Product quality: Proper sealing maintains the food’s appearance, taste, and nutritional value by protecting it from environmental factors like humidity and oxygen.

- Shelf life extension: Effective sealing helps extend the product’s shelf life by preventing spoilage and degradation.

- Consumer confidence: A well-sealed package reassures consumers that the product is fresh and safe to eat.

Methods of seal inspection

Several methods can be used to inspect and validate seal integrity, each with its own advantages and applications. Here are some common methods:

- Visual inspection:

- Description: This involves a simple visual examination of the seal to check for any obvious defects or gaps.

- Use: Suitable for quick, preliminary checks but may not detect all issues.

- Mechanical testing:

- Description: Mechanical devices apply pressure to the seal to test its strength and integrity.

- Use: Effective for identifying weak points in the seal but may be more time-consuming.

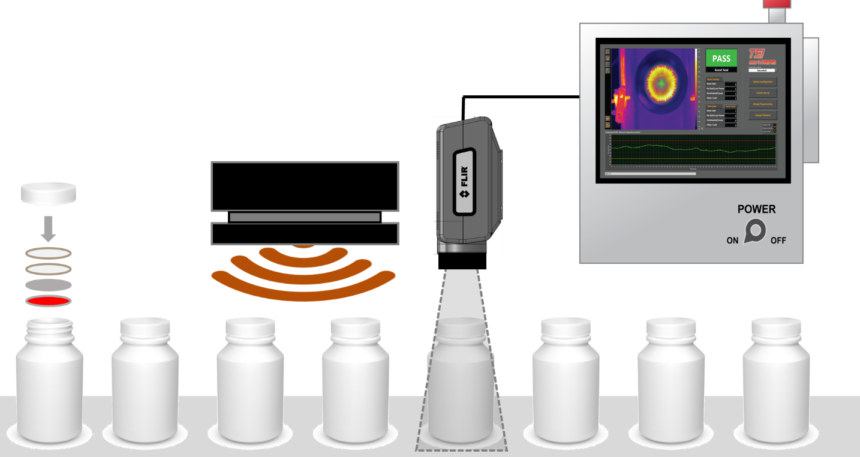

- Vision-based solutions:

- Description: Advanced vision-based systems use cameras and image processing software to detect seal defects with high precision.

- Use: Ideal for automated and high-throughput environments, offering reliable and efficient detection of seal issues.

Implementing vision-based solutions

Adopting vision-based solutions for seal inspection offers several benefits, including increased accuracy, efficiency, and consistency. Here’s how to implement such a system:

- System setup:

- Hardware: Install high-resolution cameras and appropriate lighting to capture clear images of the seals.

- Software: Use image processing software capable of detecting seal defects, such as voids, wrinkles, or contamination.

- Integration: Ensure the vision system integrates seamlessly with the existing packaging line for real-time inspection.

- Calibration and testing:

- Calibration: Regularly calibrate the cameras and software to maintain accuracy.

- Testing: Conduct initial testing with known defects to verify the system’s effectiveness.

- Continuous monitoring:

- Real-time analysis: Continuously monitor the seal inspection process to detect and address issues promptly.

- Data logging: Log inspection data for quality control and traceability purposes.

Benefits of vision-based seal inspection

Implementing vision-based seal inspection systems provides numerous advantages:

- Increased accuracy: High-resolution cameras and advanced software detect even the smallest defects.

- Efficiency: Automated inspection reduces the need for manual checks and speeds up the packaging process.

- Consistency: Vision-based systems provide consistent and repeatable results, ensuring high-quality seals across all packages.

- Cost savings: By reducing the risk of product recalls and waste, vision-based seal inspection can lead to significant cost savings.

Seal inspection plays a critical role in maintaining the safety, quality, and shelf life of packaged food products. Understanding the importance of seal integrity and adopting advanced inspection methods, such as vision-based solutions, can help ensure that the food remains safe and fresh for consumers. For businesses looking to enhance their seal inspection processes, exploring vision-based technologies can offer significant advantages in terms of accuracy, efficiency, and overall product quality.