There are different types of vacuum pumps. Each type of pump has different advantages and drawbacks, so it’s essential to understand the differences before making a purchase. Here we will explore the types of vacuum pump and help you decide which is right for your business.

Rotary Vane Vacuum Pump

A rotary vane vacuum pump is a professional-grade tool used in various settings. In general, these pumps are used to create a vacuum, which can then be used for a variety of purposes. For example, a rotary vane vacuum pump can be used to evacuate air from a sealed container, such as a computer case or refrigeration system.

This removes all the air from the container, filling it with a different gas or liquid. Rotary vane vacuum pumps can also be used to power devices that require a vacuum, such as inkjet printers or x-ray machines. When choosing a rotary vane vacuum pump, it is crucial to consider the intended use and choose a pump designed for that purpose. Otherwise, the pump may not work as intended or may even damage the equipment.

Diaphragm Vacuum Pump

As with any professional equipment, there are certain times when a diaphragm vacuum pump should be used. First, diaphragm pumps are ideal for applications where the required vacuum is relatively low – typically below 29 inches of mercury. They are also a good choice when the process gas is corrosive or otherwise difficult to handle, as they can be made from materials resistant to corrosion.

Additionally, diaphragm pumps can be used when the process gas contains particulates that could damage other types of pumps. Also, diaphragm pumps are often used in portable applications or where space is limited, as they are compact and lightweight. This pump is likely the best choice when these factors are present.

The liquid Ring Vacuum Pump

There are many instances where a professional may need to use a liquid ring vacuum pump. For instance, if in case, you are working with a material sensitive to heat, you will need to use a pump that can maintain a low temperature. If you are working with a volatile material, you will need to use a pump that can maintain a high vacuum. In addition, if you work in an environment with a risk of explosion, you will need to use a pump specifically designed for this purpose. These pumps are well suited for industrial and scientific applications, and companies like Provac Sales, Inc. offer a wide range of high-quality options to meet these demanding requirements.

Scroll Vacuum Pumps

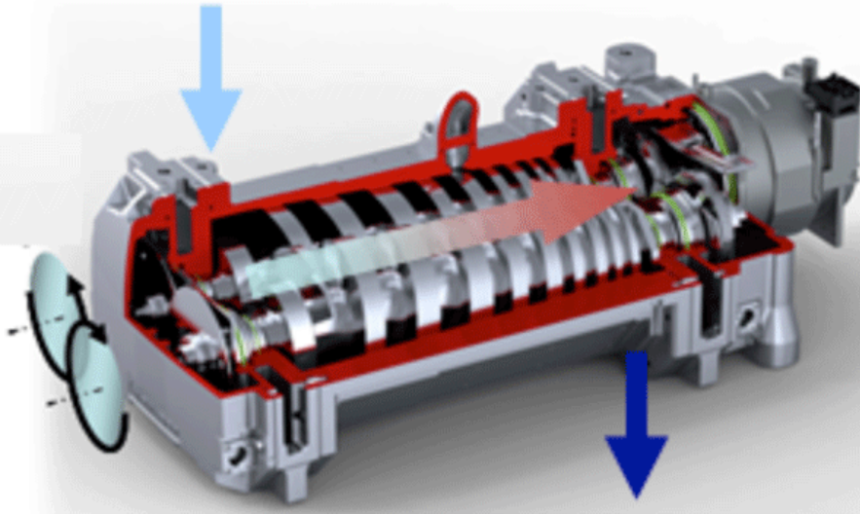

Of all the vacuum pumps on the market, scroll vacuum pumps are some of the most efficient and reliable. These pumps use a series of scroll sets to create a vacuum, meaning they can operate continuously without degradation.

Turbomolecular Vacuum Pumps

The turbomolecular vacuum pump can create a much stronger vacuum as it relies on the principles of turbulence. It creates a vacuum by passing gas particles through a turbine. The turbine is designed to spin very quickly, and it causes the gas particles to speed up as they pass through it. This increase in speed causes the gas particles to move away from each other, and this separation of the gas particles creates a vacuum.