Are you planning to either etch or engrave on metal but feel confused about which option is best? If so, don’t worry, you aren’t alone.

Understanding the main differences between engraving and etching will help you choose the best-suited method for your needs and project. Both techniques can be used for creating minute and unique designs.

Keep reading to learn more about the differences and how to choose the option that best suits your needs.

A Closer Look at the Etching Process

There are two main options if you choose to etch something. This includes chemical etching and laser etching.

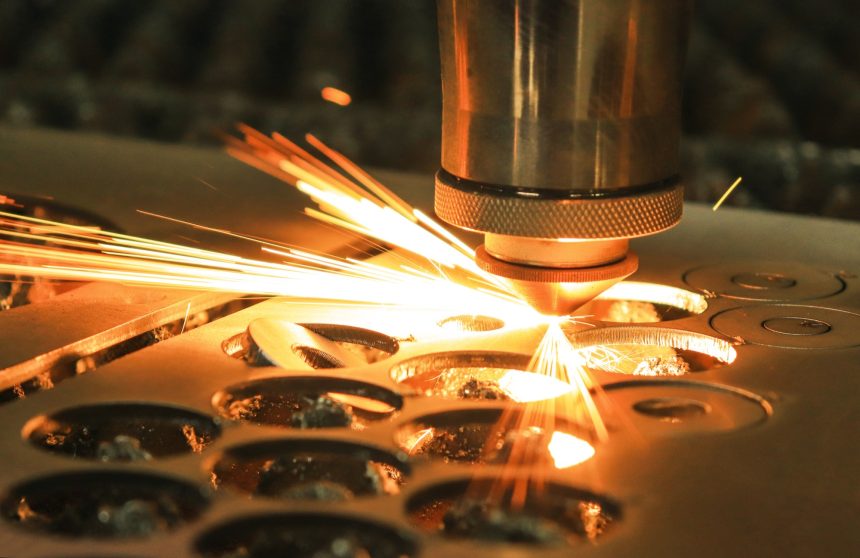

Laser etching is a popular option and just what the name implies. A high-powered laser etcher will cut into the material’s surface. It creates a permanent design.

You can etch virtually anything from a basic design or image to plain serial numbers or text.

With chemical etching, a chemical process is used that dissolves the metal material. The areas of the material you have specified are the only ones that are treated with this type of acid bath.

Durability of Etching

Etching is a cost-effective and durable process. The exposed metal material that has an etched design will usually last for five to 10 years.

If you compare this to screenprint marking, you will see it is much more durable. Since there is no ink on the material’s surface, you don’t have to worry about fading or wearing.

However, if ink fills are added, these may show signs of wear and tear. It is something you need to consider when trying to decide between etching and engraving.

If you are worried about longevity, you can opt for other processes, such as photo anodization and embossing. These last longer and provide more detailed information, like QR codes and barcodes. More about this can be found when you visit this page.

Industries That Rely on Metal Etching

Metal etching is used by many industries today. It can be found on everything from military applications to aerospace parts.

In fact, the process has now been adopted and is used by countless organizations. Some of the industries that rely on this include:

- Furniture

- Aerospace

- Locker tags

- Defense

- Automotive

- Energy

- Transportation

Like engraving, multiple materials can be used and etched. Stainless steel and aluminum are the two most common materials that are etched.

The Etch and Fill Process

A special option you have with etching is to etch and fill. After the chemical or laser etching is complete, you can add a color fill to the recess created.

This offers more customization and higher-contrast designs to the project you are working on.

A Closer Look at the Engraving Process

If you opt for engraving, rather than etching, a special fiber laser is used to carve information or a design into the metal you are using. This is often done with a higher-powered laser engraving machine or some other type of laser technology. You can find more information on Boss Laser reviews to see how that process looks.

Engraving cuts the design deeper into the material than etching does. This provides a highly visible, long-lasting marking.

One of the main drawbacks of engraving is that it can be extremely time-consuming. Every design element is cut from the material, one tag at a time.

If you have a larger quantity production, then choosing to engrave may not be best. However, for more detailed designs, choosing to engrave is a smart move.

Durability Considerations

When you choose to engrave, the project will offer a higher level of durability. Since engraving is deeper than etching, it can withstand significant wear and tear before you can’t read or see what was engraved.

Another benefit is that you don’t have ink that will fade away or rub off. Also, the engraving will be able to stand up to rougher environments.

Industries That Rely on Metal Engraving

Metal engraving is a process that is used by several industries. Some of the ones that use this process include:

- Automotive

- Defense

- Energy

- Transportation

Using engraved metal nameplates provides some level of customization. You can add your custom logo and create a unique, standout look.

You also have the option to add color to these tags using painted steel or anodized aluminum. This process adds just one color to the material.

Customization Options from Metal Engraving

There are several customization options if you choose metal engraving. For example, you can customize the holes, material thickness, and corners of the project.

You can also choose a custom shape and use a colored inlay. Each of these customization features helps you create something that is truly unique.

Because of these customization options, metal engraving has become more popular in recent years. The high level of durability helps with this, as well.

Metal Engraving or Metal Etching: Which Option Is Right for You?

If you are trying to decide if you should use metal engraving or metal etching for your project, it’s a good idea to review the information above once more. Doing so will help you choose a process that best suits your needs.

Also, in most cases, the cost and time factors will play a part in your decision. Consider all this carefully to ensure the option selected works with your specific needs. Being informed will help you decide between metal etching and metal engraving.

Did you find the information above helpful? Are you looking for more resources on topics like health, finance, business, and sports? If so, be sure to check out some of the other blogs on our site.

The amardeep steel pipes manufacturer offers seamless steel pipes to its clients. These pipes are manufactured using state-of-the-art technology, which is why they are highly durable and easy to use.