Silicon wafers play a crucial role in the world of integrated circuits, which are essential components in almost all electronic devices. From smartphones to computers and even household appliances, integrated circuits enable these devices to work efficiently. Understanding why silicon wafers are so important can help demystify how technology operates at a fundamental level.

- What Are Silicon Wafers?

- The Importance of Silicon in Integrated Circuits

- How Are Silicon Wafers Made?

- From Wafers to Integrated Circuits

- Challenges in Silicon Wafer Production

- Environmental Considerations

- How Silicon Wafers Impact Our Daily Lives

- Future of Silicon Wafers in Technology

- The Role of Silicon Wafers in Future Innovations

- The Unseen Heroes of Technology

Read on to learn about silicon wafers and their role.

What Are Silicon Wafers?

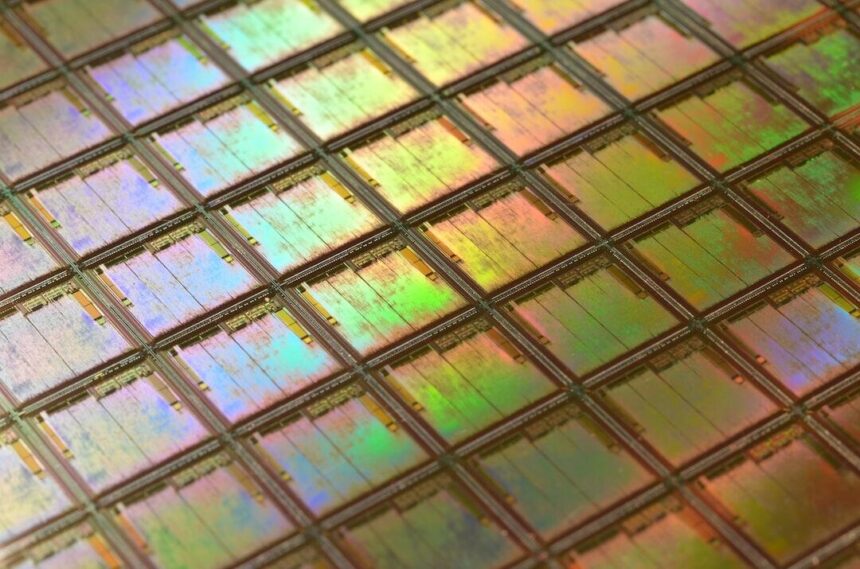

Silicon wafers are thin slices of silicon that are used as a substrate for fabricating microchips. These wafers are usually between 0.5 mm to 1 mm thick. They start as large blocks of silicon known as ingots, which are created by melting silicon crystals together.

Once the ingots have cooled down, they are sliced into thin, flat pieces-this is what we refer to as silicon wafers. The flat surfaces of these wafers create the perfect foundation for laying down various electronic components.

The Importance of Silicon in Integrated Circuits

But why use silicon specifically? Silicon is a semiconductor, which means it can conduct electricity under certain conditions. This property makes it ideal for electronic applications.

When silicon is combined with tiny amounts of other elements, it can either conduct electricity or act as an insulator. This ability to switch between conducting and insulating makes silicon a versatile material, necessary for creating the transistors needed in integrated circuits.

How Are Silicon Wafers Made?

The manufacturing process for silicon wafers is a multi-step operation that requires precision and expertise. The process starts with raw silicon, which undergoes purification to eliminate impurities.

After purification, the silicon is placed into a furnace where it is melted. Next, a seed crystal is dipped into this molten silicon to encourage the growth of a larger crystal. Once the large crystal, or ingot, has formed, it is carefully removed and cooled down.

After cooling, the ingot is sliced into thin wafers using specialized saws. These wafers must be polished to achieve a smooth surface, which is essential for the next steps in chip manufacturing. Any imperfections could impact the performance of the final product.

From Wafers to Integrated Circuits

Once the silicon wafers are ready, they enter the realm of semiconductor fabrication. This process involves a series of steps where various materials are deposited, patterned, and etched onto the wafer surface to create functioning microchips. These steps include photolithography, ion implantation, and chemical vapor deposition, among others.

During photolithography, a light-sensitive material is applied to the wafer’s surface. A pattern representing the desired circuit design is then projected onto it using ultraviolet light.

The exposed areas of the photoresist are removed, leaving behind a patterned surface for subsequent layers to be added. This intricate design will ultimately define how the integrated circuit operates.

Challenges in Silicon Wafer Production

Producing silicon wafers and the chips that come from them is not without challenges. Controlling the quality of both the silicon and the manufacturing processes is critical and complex.

Even the slightest deviation in temperature or chemical concentration can lead to defective wafers, which need to be discarded. Furthermore, advancements in technology have pushed for a demand for smaller and more efficient chips, leading to finer features on the wafers. This requires specialized equipment and techniques to achieve.

Environmental Considerations

As with any industry, there are environmental factors to consider when producing silicon wafers. Production processes can produce waste and emissions that might harm the environment.

However, many companies are now focusing on becoming more sustainable by adopting greener practices. This includes recycling waste materials and reducing energy consumption during the wafer fabrication process.

How Silicon Wafers Impact Our Daily Lives

The significance of silicon wafers reaches far beyond just manufacturing. Since they are embedded in practically all electronic devices, they have a profound impact on our daily lives.

Every time we use a smartphone or a computer, we rely on integrated circuits made from silicon wafers to perform tasks efficiently. These circuits make possible the rapid processing and transfer of information that we often take for granted.

Moreover, the miniaturization of electronics has occurred largely because of advancements in silicon wafers. The ability to create smaller circuits has led to the development of compact devices that pack powerful features into user-friendly designs. Our modern world would be quite different without the contributions of silicon wafers in integrated circuit technology.

Future of Silicon Wafers in Technology

Looking ahead, silicon wafers will continue to play a pivotal role in the evolving landscape of technology. As industries demand faster and more efficient devices, ongoing research is focused on improving the performance of silicon wafers. Innovations in materials science could see new types of wafers that further enhance conductivity and reduce power consumption.

Also, as the Internet of Things (IoT) and artificial intelligence (AI) blend more into our lives, the need for better silicon wafers is set to rise. These advancements will lead to smarter devices. They will communicate with each other and respond better to user needs.

The Role of Silicon Wafers in Future Innovations

Silicon wafers are the backbone of countless technologies that define our modern existence. Their unique properties can be manipulated at the microscopic level. This allows for new designs that create efficient integrated circuits.

As we go further into the digital age, silicon wafers will play a bigger role. They will help create futuristic technologies that we are just starting to imagine.

The journey of a silicon wafer is fascinating. It starts as a simple material and becomes a key part of modern electronics. This process shows the amazing advancements in science and technology.

The Unseen Heroes of Technology

By understanding the role of silicon wafers in integrated circuits, we can appreciate the complexity and innovation that drive our technological world. From their creation to their application in electronic devices, silicon wafers are indispensable to modern electronics. As technology continues to evolve, so too will the significance of silicon wafers, leading to innovations that we will rely on now and in the future.

Next time you use your device, remember the vital role these tiny silicon wafers play, helping to connect us and enhance our lives.

If you enjoyed this article and would like to read more like it, please check out the rest of our blog today.