Are you in the early stages of a construction project and confused about choosing from the numerous available composite materials? When looking into composite fabrication, it is important to familiarize oneself with the several terminologies used because composites can give the impression of being difficult to understand.

In this post, we will go over the fundamentals of glass reinforced plastic (GRP), which is also commonly referred to as fiberglass.

What Is GRP?

Glass Reinforced Plastic, more commonly referred to as fiberglass, is a popular choice as a building material across various sectors. The first documented use of glass fibers dates back to 1880, and since then, the material has undergone numerous transformations.

What Is GRP Made Up of?

GRP consists of polymer matrix and glass fibers. The composite material can employ polymers like vinyl ester, epoxy, or polyester thermosetting resin depending on the application of the final product; however, the type of polymer utilized is determined by the product’s intended use. It’s possible to incorporate the glass fibers into the composite material in various ways, such as placing them randomly throughout the material, weaving them into a glass cloth, or flattening them into a sheet.

When Is GRP Used?

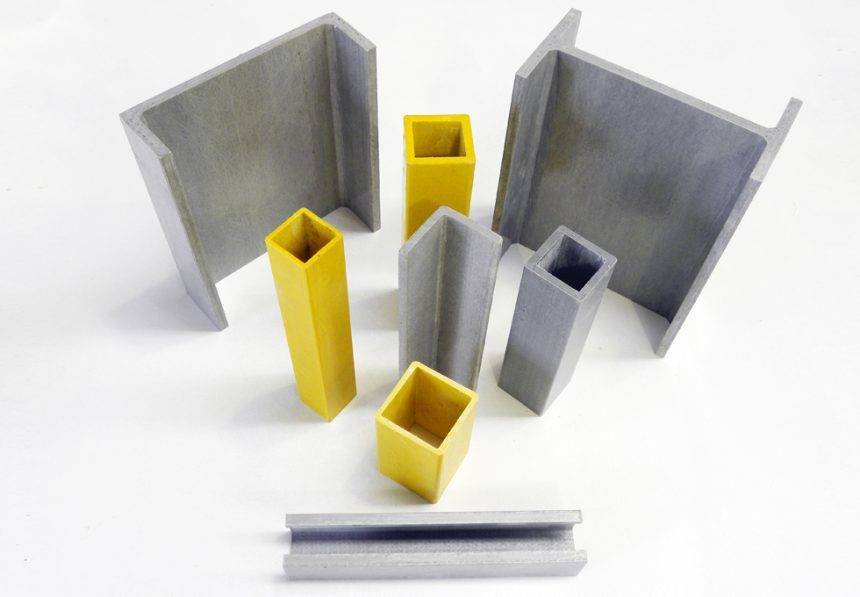

Protecting industrial structures with GRP pultruded profiles is an excellent choice compared to traditional materials such as steel and timber because these profiles are cost-effective, long-lasting, and resistant to corrosion.

GRP profiles are known for their exceptional strength and sturdiness, and they are available in a wide range of shapes and dimensions so that they may be customized to meet the requirements of any given application. GRP profiles are preferable for commercial and industrial applications because they are manufactured from isophthalic polyester resin and reinforced with E glass fiber for additional strength.

Benefits of Glass Reinforced Plastic

There are many benefits to using fiberglass-reinforced polymers as building materials, including the following:

- Non-Conductive – Since GRP does not allow electricity to flow through it, it is an excellent material to use in locations with high electrical output. This includes on and near railways and while electrical components are being manufactured.

- High Corrosive Resistance – Because it has great corrosion resistance, fiberglass can be utilized in settings where other materials cannot. This is partly attributable to the resins that protect against a varied pH range.

- Durable – GRP is long-lasting and can handle various stresses, including degradation, pressure, and regular wear and tear. Because of this, the products created with it can have a long shelf life and keep their perfect condition for an extended period.

- Cost-Effective – GRP can save you significant money compared to many other building materials. During their useful lives, molds made from GRP require very minimal maintenance in the form of repairs and maintenance. In the same vein, because it is so hard-wearing and resistant to corrosion, it wears down slower and requires less repair throughout its lifetime.

The Bottom Line

Because of its one-of-a-kind properties, GRP profiles are gradually replacing more traditional materials such as aluminum and steel. It has become the premium choice for engineers, technicians, and designers. The possible applications for items made of GRP are virtually endless.

There are applications for items built partially or totally from GRP materials in virtually all markets if designed imaginatively and subjected to engineering verification. Speak to a GRP expert today to find out if it’s right for your project.