Cam follower bearings, also commonly known as track rollers, play an essential role in numerous mechanical and automotive applications. As one of the critical components of the modern machinery that shapes our world, understanding cam followers’ function, unique features, and the vast array of benefits they offer, can prove pivotal. This blog post delves into the intricacies of cam followers bearing, taking you on a journey through their fundamental purpose, structure, characteristics, and potential uses.

The Function of Cam Followers Bearing

Cam follower bearings are a type of rolling-element bearing that follows tracks or cams and are part of a wide range of mechanical systems. They convert rotational motion into linear motion, a function that allows them to perform various tasks, including transferring energy, distributing load, and reducing friction.

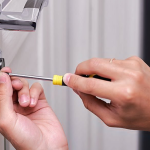

A typical cam follower bearing consists of a thick-walled outer ring, a needle roller, and a stud that houses the needle roller and enables it to roll freely. The stud is often threaded at one end and features a hexagonal hole at the other end for mounting purposes.

In applications, cam followers bearing are guided by the cam profile while being held in the cam follower carriage, which is part of the machine’s framework. The cam profile can be linear or curved, and the cam follower moves accordingly, translating the rotational motion of the cam into linear motion.

Key Features of Cam Followers Bearing

Several distinct characteristics distinguish cam followers bearing from other types of bearings:

1. Design Flexibility: Cam followers come in a variety of designs, sizes, and types, providing substantial flexibility to meet different application requirements. They are available in stud type and yoke type, with variations including crowned outer ring, cylindrical outer ring, and sealed versions.

2. Load Capacity: Owing to their thick-walled outer ring, cam followers are highly resilient, capable of withstanding heavy loads and shocks. The needle rollers distribute the load evenly across the bearing, reducing stress on individual components and increasing overall bearing life.

3. High Speed and Low Friction: The design of cam followers allows for high rotational speeds, while the needle rollers ensure low friction and smooth operation, contributing to improved machine performance.

4. Maintenance-free: Many cam followers bearing are pre-greased and sealed, requiring minimal to no maintenance, providing substantial advantages in terms of reduced downtime and cost savings.

5. Easy Installation: The stud type cam followers can be quickly and conveniently installed directly onto the machine component, saving time and effort during assembly.

Applications of Cam Followers Bearing

Cam followers bearing find utility in a wide array of applications due to their unique features:

1. Conveyor Systems: In conveyor systems, cam followers are used to guide and support the conveyor belt, maintaining tension, and ensuring smooth belt operation.

2. Packaging Machinery: Packaging machines often utilize cam followers for precise, linear motion to guide packaging components accurately.

3. Automotive Applications: In engines, cam followers serve as the intermediary between the camshaft and the valves, following the cam profile to open and close the valves at the correct times.

4. Printing Presses: In printing machines, cam followers contribute to the precise motion control necessary for ensuring high-quality print output.

The Evolution of Cam Followers Bearing

As with many other mechanical components, cam followers bearing have not been stagnant in their development. Over time, manufacturers have made significant improvements to adapt to the evolving needs of various industries. Advancements in materials science have led to cam followers bearing being constructed with more robust and durable materials, capable of withstanding higher temperatures and harsher environments. Modern designs have also incorporated features such as integrated seals for better protection against contaminants and lubrication retention, ensuring extended operational life and reliability.

Customization and Special Types

Beyond the standard types of cam followers, many manufacturers also offer custom solutions to cater to the unique needs of specific applications. For instance, some cam followers bearing are specially designed to operate under extreme temperatures, while others are constructed to resist corrosion in highly acidic or salty environments. There are also eccentric cam followers, where the stud is eccentric to the center of the bearing. This eccentricity can be adjusted to provide different levels of cam engagement, allowing for more precise control over the motion output. These tailored solutions underline the versatility of cam followers bearing and their adaptability to diverse operational requirements.

The Future of Cam Followers Bearing

Looking to the future, the potential for innovation within the cam followers bearing industry is vast. With the advent of smart manufacturing and the increasing use of automation and robotics, there is a growing demand for bearings that can deliver greater precision, speed, and durability. As such, we may see the development of ‘smart’ cam followers equipped with sensors that monitor their performance in real-time, providing feedback that can be used to optimize operational efficiency. There is also scope for improvements in the area of materials, with the potential use of advanced composites or nano-materials to enhance the durability and performance of cam followers. As technology continues to evolve, it is certain that cam followers bearing will continue to adapt and grow, remaining a fundamental component in the world of mechanical engineering.

In conclusion, cam followers bearing are integral to the functioning of numerous mechanical systems. Their function of converting rotational motion into linear motion, along with their remarkable features such as design flexibility, high load capacity, high speed, low friction, maintenance-free operation, and easy installation make them indispensable in many applications. Whether it’s in the automotive industry, packaging machinery, printing presses, or conveyor systems, cam followers bearing continue to shape our world, silently contributing to the complex mechanisms that drive modern industry.

As advancements in technology continue to push the boundaries of what’s possible, one can expect even more innovative applications of cam followers bearing, further attesting to their importance and versatility in the world of mechanical engineering. With a keen understanding of their function and features, industry professionals and enthusiasts alike can fully harness the potential of these remarkable mechanical components.