In the world of defense contracting, the demand for custom military machining services is growing as military projects require impeccable precision and durability. With defense budgets increasing and technology advancing, having reliable and precise machining services can make a significant difference in the outcome of critical operations.

Whether it’s for aerospace, arms, or naval applications, the need for high-quality components cannot be overstated. Keep on reading if you want to learn more.

Why Choose Reliable Custom Military Machining Services?

Choosing the right machining service for military projects is crucial. A reliable partner will not only provide high-precision parts but also ensure that these components adhere to the stringent standards required in the military industry. Factors to consider when selecting a machining service include:

Experience in Military Contracts

Choose a service that has worked with the military before. They know the rules and what is expected. This makes fewer mistakes and saves time.

Certifications and Compliance

Make sure the company has the right papers and follows the rules. These show they do good, safe work. It also means they can handle special jobs the right way.

Advanced Technology

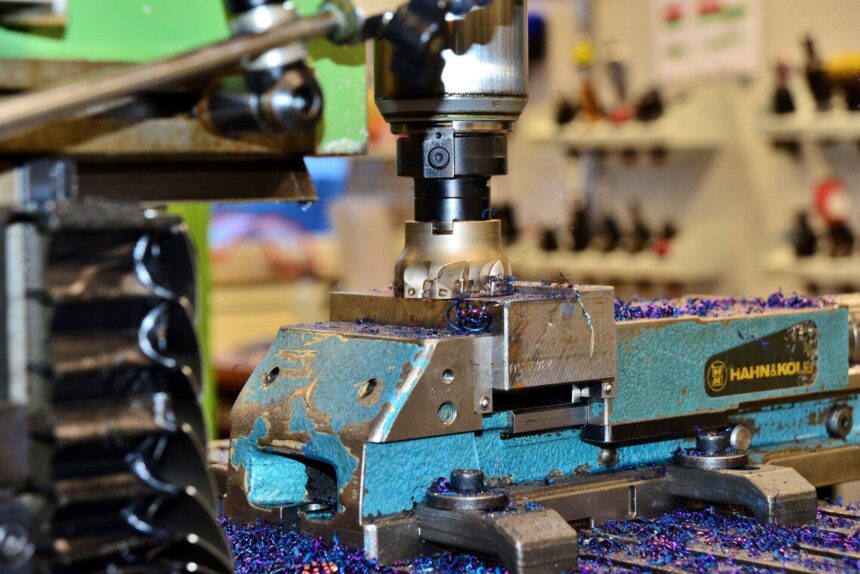

New machines can do better work. They are faster and more exact. This helps your project finish on time and with better results.

Custom Solutions

Each job is different and may need special tools or steps. A good company can change how it works to fit your needs. This gives you better results for your project.

Understanding the Importance of Quality Standards

Quality assurance is a very important part of military machining. Parts used in defense need to be strong and work well, even in tough conditions. To make sure of this, companies use special checks and tests during the process.

One method is non-destructive testing (NDT), which checks parts for problems without breaking them. Another is dimensional inspection, where parts are measured carefully to see if they match the needed size. Traceability systems are also used to keep track of materials and steps taken during production. This helps find where problems come from if something goes wrong.

By following these quality steps, military machining companies make sure their parts are safe and reliable. This helps keep defense systems strong, missions successful, and people protected.

The Future of Military Machining Services

Technology keeps changing, and military machining is changing too. New tools like automated machines, 3D printing, and better materials help make parts faster and better. These new ways help defense projects in many ways.

First, parts can be made much quicker, so orders arrive sooner. Second, machines can make shapes and designs that were hard or impossible before. Third, these methods can save money, making good parts easier to get for both big and small projects.

Because of this, companies that work on military parts need to keep up with new technology. They should use these new tools to stay strong and win more contracts.

Partner with Experts in the Field

To sum up, custom military machining services are very important for defense projects that need strong and precise parts. As defense spending grows and technology gets better, working with skilled and certified machining companies helps make sure parts are made well and meet tough rules. Using new tools like automated machines and 3D printing helps make parts faster, in better shapes, and cheaper.

For more related topics, check out the rest of our blog!