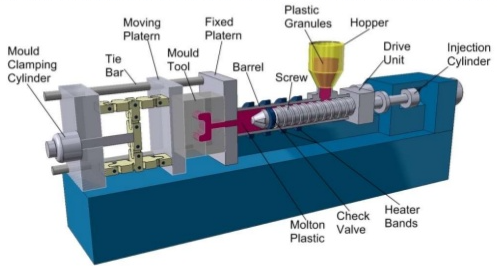

Plastic injection molding has become a popular manufacturing process due to its versatility, efficiency, and cost-effectiveness. It involves injecting molten plastic into a mould cavity to create a desired shape, which can then be used to make a wide range of products. From automotive parts to household items, Plastic injection molding is used to create a variety of products.

- Advantage 1: high precision

- Advantage 2: Versatility

- Advantage 3: cost-effectiveness

- Advantage 4: Fast Production

- Advantage 5: Material Options

- Advantage 6: Environmentally Friendly

- Advantage 7: Consistent quality

- Advantage 8: Design Flexibility

- Advantage 9: Reduced Post-Production Operations

- Advantage 11: Eco-Friendly Manufacturing

In this article, we will discuss the advantages of Plastic injection molding in detail. Let’s get started! (Click Here)

Introduction:

Plastic injection molding is a manufacturing process that has been used for decades to create high-quality, precision parts at a low cost. It involves melting plastic pellets and injecting them into a mould, where they cool and solidify into the desired shape. The process is versatile and can be used to create complex parts with intricate geometries.

Advantages of Plastic injection molding:

Advantage 1: high precision

One of the major advantages of Plastic injection molding is precision injection mold. This manufacturing process is capable of producing parts with very tight tolerances, ensuring that the final product is of consistent quality. This precision is possible due to the use of computer-aided design (CAD) software and advanced machinery, which allow for accurate control of the injection process.

Advantage 2: Versatility

Another advantage of Plastic injection molding is its versatility. This manufacturing process can be used to produce parts of various sizes and shapes, from small components to large parts. The flexibility of Plastic injection molding allows for the production of complex parts that would be difficult or impossible to produce with other manufacturing methods.

Advantage 3: cost-effectiveness

Plastic injection molding is a cost-effective manufacturing process, particularly when producing large quantities of parts. The initial investment in tooling and equipment can be high, but the cost per part decreases as the volume of production increases. Additionally, the use of automation and robotics in Plastic injection molding can further reduce labour costs and increase efficiency for plastic molds manufacturer.

Advantage 4: Fast Production

Plastic injection molding is a fast production process, allowing for the rapid production of large quantities of parts. This is due to the high-speed injection of molten plastic into the mould, which solidifies quickly. With this manufacturing process, parts can be produced in a matter of seconds, making it an ideal choice for time-sensitive projects.

Advantage 5: Material Options

Plastic injection molding offers a wide range of material options, including both thermoplastics and thermosetting plastics. This allows for the production of parts with a variety of properties, such as strength, flexibility, and heat resistance. Additionally, Plastic injection molding can be used to produce parts with specific surface finishes, such as texture or gloss.

Advantage 6: Environmentally Friendly

Plastic injection molding is an environmentally friendly manufacturing process. It produces little to no waste, as excess plastic can be recycled and reused. Additionally, the process itself is energy-efficient, as it requires less energy than other manufacturing methods.

Advantage 7: Consistent quality

Another advantage of Plastic injection molding is its ability to consistently produce high-quality parts. The use of sophisticated machinery, combined with advanced materials and a controlled manufacturing process, ensures that each part is identical to the last. This makes Plastic injection molding a reliable and consistent manufacturing process, which is essential for industries that require precision and consistency in their products. Additionally, the use of automated quality control systems can further improve the consistency and reliability of the manufacturing process, ensuring that every part meets the required standards.

Advantage 8: Design Flexibility

Plastic injection molding offers a high degree of design flexibility, allowing for the production of parts with intricate geometries and complex shapes. This is due to the ability to produce parts with multi-cavity moulds, which can produce several identical parts in a single cycle. Additionally, the use of insert moulding allows for the incorporation of metal, ceramic, or other materials into plastic parts, providing even greater design flexibility. The ability to produce complex and innovative designs makes Plastic molding an ideal choice for industries such as automotive, medical, and electronics, where the demand for unique and specialised parts is high.

Advantage 9: Reduced Post-Production Operations

A major advantage of case studies is over other manufacturing processes as it can produce parts with finished surfaces, reducing the need for post-production operations. The use of advanced injection moulding technology, such as gas-assisted injection moulding, can further improve the surface finish of parts, reducing the need for additional operations such as sanding or painting. This can save time and reduce costs, as post-production operations can be time-consuming and expensive. The ability to produce parts with finished surfaces also makes Plastic injection molding an ideal choice for industries that require high-quality finishes, such as the consumer goods and automotive industries.

Advantage 11: Eco-Friendly Manufacturing

Plastic injection molding is an eco-friendly manufacturing process, as it generates minimal waste and reduces energy consumption. The use of advanced moulding technologies, such as gas-assisted injection moulding, can further reduce material waste as less material is required to produce parts. Additionally, many of the plastic materials used in injection moulding are recyclable, reducing the environmental impact of the manufacturing process. The automation of the manufacturing process also reduces energy consumption, as the process is more efficient and requires less energy to produce parts. The eco-friendliness of advantage molding makes it an ideal choice for industries that prioritise sustainability and environmental responsibility.

Conclusion:

Sinomould, Plastic molding offers numerous advantages over other manufacturing processes, including high production efficiency, cost-effectiveness, accuracy, versatility, consistent quality, design flexibility, reduced post-production operations, and scalability. These advantages make it an ideal choice for a wide range of industries, including automotive, medical, electronics, and consumer goods. The use of advanced technology and materials has further improved the capabilities of Plastic injection molding, making it one of the most reliable and efficient manufacturing processes available today. With its ability to produce complex and innovative designs, consistent quality, and scalability, Plastic injection molding is likely to remain a popular choice for manufacturers for years to come.