Most thread failures that you see don’t come from weak material or bad machining. They come from wrong choices, like the tap pitch is too tight, or the hole size is too loose, or the tap just is not suited for the job.

Therefore, this guide will help you make better choices next time you reach for a tap.

Know the material before anything else

Different metals behave differently when you cut them. It’s obvious. But what’s not obvious is how much material properties affect your tap pitch and diameter.

Hard materials, like stainless steel or titanium, need more clearance. If your pitch is too fine, you’ll get chip packing. The tap will break, threads will strip, and you’ll waste time. On the other hand, soft materials like aluminium or brass don’t need as much clearance. But go too coarse on the pitch and your threads won’t hold under stress.

Now here’s the part most folks ignore – ductility.

Ductile metals stretch. If your tap pitch is off, it can distort the threads as it cuts.

Select diameter based on core strength, not nominal size.

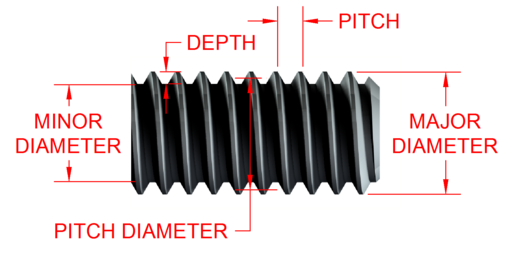

Sometimes people make the mistake of picking a tap based on nominal thread size and run with it. But what matters is the minor diameter. It’s the inner part of the thread, where the material carries the load.

If your hold is too small, you overstress the tap, and if it’s too large, the thread won’t hold under torque.

To get it right, you’ve got to consider the core strength of the part you’re threading. Think about what forces that threaded part will handle. Pull, shear, vibration?

Once you know the load type, you can calculate how deep the thread needs to go and what the best minor diameter is for that load. And in tough materials, going slightly oversize on the hole also reduce tap wear. You’ll still get enough thread engagement, but with less friction.

Match the tap pitch to the thread engagement, not just size

Machinists go by thread size charts, but these charts don’t tell the full story. Thread pitch affects how much surface area is making contact between the screw and the material. This is what holds things in place, not only the number of threads.

If you’re working with shallow holes, fine pitch often seems like the right call. But sometimes, a coarser pitch with fewer threads gets the job done better. It gives more chip room, easier tap withdrawal, and less friction.

Especially when tapping blind holes, your tap pitch must leave room for chips. If it doesn’t, the chips get compacted and crack the threads. You might not see the damage right away. But threads will fail under load.

This is even more true with pipe taps. These are used for fluid-tight seals, usually in blind holes. That means you need the right pitch and taper. Too fine, and you risk weak seals. Too coarse, and the tap may jam or miscut.

Consider coatings and tap geometry together.

You may consider changing the tap coating, but do you consider changing the tap geometry?

A coated tap cuts differently than an uncoated one. Some coatings reduce friction while others make the tape harder but more brittle. If you change the type of tap, such as switching from a straight flute to a spiral flute, you should reconsider your pitch and diameter, too.

Form taps, for example, don’t cut at all. They reshape the material. Which means your hole size needs to be slightly larger to begin with. And the thread pitch might need adjusting based on the material flow.

Check machine limits before finalizing tap specs.

You can’t ignore the machine. If your machine has low torque or flexible tooling, you may need to change your tap diameter or pitch to avoid chatter and misalignment.

Rigid tapping needs exact specs, but floating holders give some flexibility. Either way, your toolpath, spindle speed, and hole depth all matter.

If your machine can’t handle a tight pitch in hard steel ,don’t force it. Choose a more forgiving tap and go slightly looser on fit, if possible.

Conclusion

To choose the right tap pitch and diameter, start by asking the right questions before the job starts.

What’s the material? How deep is the hole? What kind of load will the thread take?

Answer those, and you’ll start making better decisions.