Choosing the right gasket or sealant for your needs is an important decision. With this guide, we’ll walk you through the basics of what to look for in a good gasket or sealant, so that you can pick the perfect one to meet all your requirements.

Whether you’re sealing connections on plumbing pipes, automobile engines, boilers and heaters, pumps and types of machinery, or any other device — you will learn how easy it is to choose the right type of gasket or sealant. Keep reading!

Understanding Your Gasket Requirements

When it comes to gaskets, it’s vital to understand the specific requirements of your application. Will your gasket be exposed to extreme temperatures, high pressures, or both? Taking the time to consider these factors beforehand can save you time, money, and frustration down the line. If you are looking for abrasion-resistant gaskets, then you should look for EPDM rubber gaskets, as this material is specifically used for applications that include hydrocarbon oils and petroleum products. Different materials and designs perform differently based on the demands of the application, so it’s important to do your research to ensure you choose the right gasket for your needs.

With our tips in mind, you can make an informed decision and feel confident in the reliability of your chosen gasket.

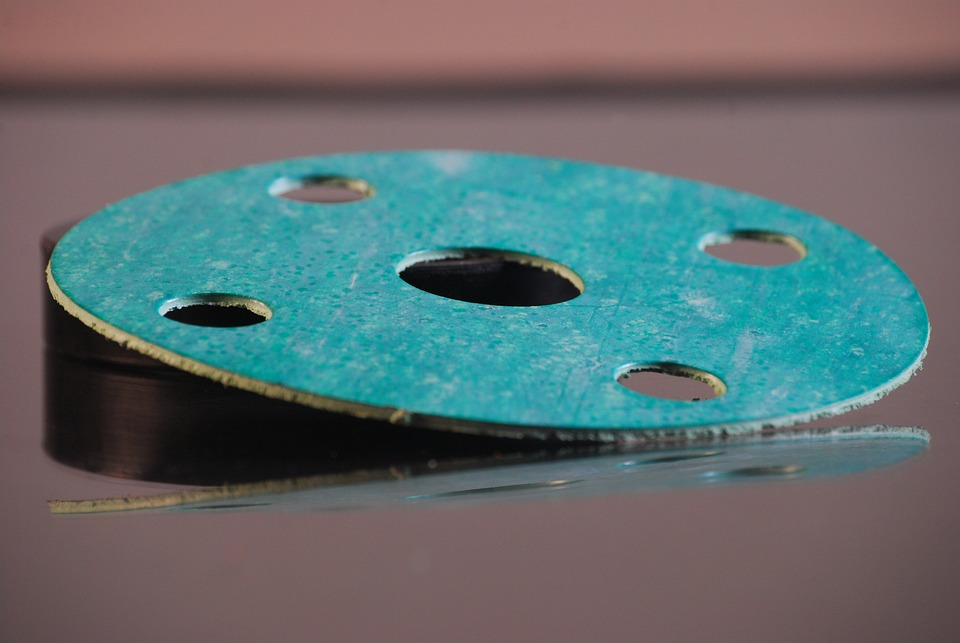

Types of Gaskets

When building or repairing machines, gaskets are a crucial component that helps achieve a secure seal between two surfaces. While gaskets may seem like a small detail, their role is quite significant in ensuring machines operate efficiently and safely. That’s why you need to select the right type of gasket for each specific application.

Rubber gaskets are common, and their flexible properties suit a variety of applications. Metallic gaskets, on the other hand, offer excellent sealing properties in high-temperature and high-pressure environments. And foam gaskets provide a lighter weight option for applications where weight is a factor. Understanding the different types of gaskets available will help you make the best choice for your specific industry and application.

Selecting The Right Material

Choosing the right material for a gasket can make all the difference in ensuring the proper function of your equipment. It’s important to consider key factors such as the chemicals that will be used with the gasket, as well as the flange surfaces that will make contact with it. By taking these into account, you can select a material that is best suited to withstand the demands of your application.

For example, certain chemicals may require a gasket made from a specific material in order to maintain integrity and prevent leakage. With the right material, you can feel confident that your equipment will operate safely and efficiently.

Choosing an Appropriate Sealant

When it comes to choosing the right sealant, it’s important to understand the differences between silicone-based and silicone-free options. Silicone-based sealants are durable and waterproof, making them ideal for areas prone to moisture like bathrooms and kitchens.

However, if you’re working with materials that are sensitive to chemicals, such as natural stone or certain metals, a silicone-free sealant may be the better choice. These sealants tend to be more eco-friendly and have a lower risk of affecting the appearance or performance of your materials. Ultimately, the decision between silicone-based and silicone-free sealants will depend on your specific needs and the materials you’re working with.

Measuring and Cutting the Gasket

Taking the time to do a dry fit of the components beforehand can save you a lot of frustration and waste materials in the long run. Once you have your measurements, make sure to use a clean, sharp cutting tool to ensure a clean cut.

It’s also crucial to follow the manufacturer’s instructions and recommended materials to ensure the gasket will function properly. With proper measurement and cutting techniques, you can create a reliable gasket that will keep your machinery running smoothly.

Installing the Gasket

Once you’ve cut the gasket, it’s time to install it. For best results, you should start by placing the gasket in place and then gently pressing down around its edges with your fingers or a soft cloth. This will ensure that it fits securely into place and forms an even seal along each surface.

Once the gasket is in place, you’ll need to use an appropriate sealant to secure it into position. Be sure to follow the manufacturer’s instructions and apply the sealant evenly along all of the surfaces. So you’re sure no leaks occur when your machinery is running.

From understanding how the gasket will be used and considering temperature ranges and pressure ratings to choosing the appropriate material and sealant, every step must be taken with careful deliberation. It’s also wise to check out all of the available options on the market in order to determine the best type of gasket for your needs.

But ultimately, having a proper measurement and cutting plan followed by a dry fit will ensure that you end up with a product that works perfectly in your application. Choosing a good gasket can be quite tricky but with diligent research and thorough assessment, you can guarantee yourself a successful project.