Using new technology, the production of electric traction drives for the automotive industry is able to maintain high productivity, a higher level of process dependability, and more fault tolerance to provide cost-effective and competitive products with a minimal amount of waste.

However, there are a few new challenges when it comes to industrial applications using these drives since there are higher needs for power density, efficient operation over a wide speed range, reduced noise emission, and the need for robustness against environmental influences. As a result of these vast demands for electric traction drives for automobiles, a highly novel field of research for engineers, as well as manufacturing technologists, has been developed.

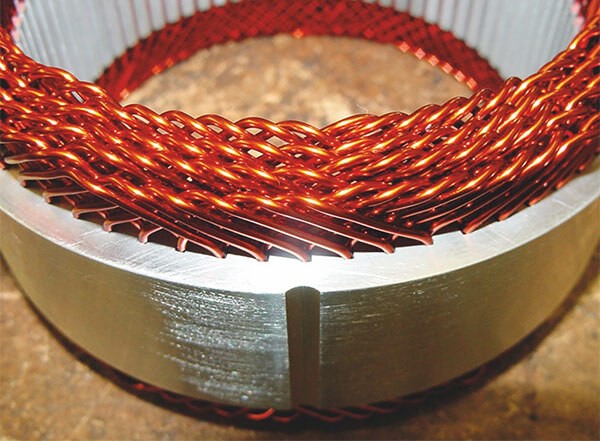

In recent times, hairpin technology, which has benefited from wide-ranging advancements in the supply chain, has established itself as an alternative method for producing high-quality stators to improve the power transmission efficiency of an automobile. Additionally, the manufacturers can minimize the copper computation for substantial automobile losses in order to increase efficiency.

Hairpin Motor & Winding

Hairpin motor winding offer the advantage of enabling a highly automated manufacturing process when used in conjunction with state-of-the-art hairpin winding technology. There are two distinct production procedures for hairpin windings, including axially and radially inserted hairpin windings, respectively. In the context of windings, the axial inserted hairpin windings conductor is twisted into a U-shaped and then put into stator slots. Furthermore, the conductor’s end is bent and welded together during the whole welding process. Similarly, a radially inserted hairpin windings conductor is bent to shape the complete winding and then put into the stator slots. The main advantage of this method is that it eliminates the requirement for welding in order to connect neighboring hairpins. Additionally, the winding’s reliability can be increased, and the winding’s manufacturing process can be improved.

Furthermore, the hairpin windings have the advantage of facilitating the automatic production process using state-of-the-art grinding machines. However, due to high barriers to machinery, technology, and building materials, it prevents the widespread use of new power vehicles. There is a slight variation in the possible configuration of the zigzag hairpin. Products are customized solutions for automotive production lines.

Advantages & Disadvantages

- Factor can reach -0.75, compared to 0.4-0.6 for standard rotating wires.

- Low electric noise.

- Better thermal performance.

- Enable the most automated production process.

- Low flexibility of winding adjustment.

Hairpin Stator & Winding

The hairpin coil methods are still so unique that comparatively few completely automated solutions are commercially available. The overall procedure typically takes the following steps: Hairpin forming involves straightening, cutting, stripping, and bending of rectangular-shaped copper wire. The next step comprises collecting (sorting and selecting of fully automatic formed pins). Thirdly, insulation paper is inserted into the stator slots. Furthermore, the twisting and bending of the hairpin ends follow the wiring scheme. Finally, welding of hairpins is done as per the connection scheme. The hairpin motor production line is well suited for the manufacture of stator wire motor stators. In terms of output, the hairpin stator has a large capacity. In terms of the production line of the hairpin stator, it provides high output. Furthermore, the equipment’s versatility enables clients to make hairpin stators of varying shapes and sizes, resulting in identical plant motors with varying technical characteristics.

Advantages & Disadvantages

- The mechanical strength level is very high.

- Rapid production of resources.

- It is easy to strengthen the construction of critical communication between operators.

- It is well suited for cooling the liquid.

- Performance improvement and reliability.

Design

A zigzag hairpin is used to improve the efficiency and power of an electric tow vehicle. The hairpin brass hair shaft is robust, reducing resistance and enhancing thermal performance. The final size of the curve on a car with short hair is smaller than the final size of the curve on a round wire, which minimises copper loss. It enhances the efficiency level, which means that the car may operate more efficiently in urban and heavy traffic environments. By and large, the thicker approach utilizing a toroidal coil has a restriction, which is the presence of unwanted spaces between the coils. However, a thicker path can lessen the spacing between the coils, resulting in a larger space area than with rowing. The regular shape of the flat wire applied to the hair shaft decreases heat resistance in the stator slot, further improving high strength and continuous performance.

Manufacturing Process

The machines perform the processes of slot insertion, hair extensions and insertion, enlargement and twisting, cutting, resetting, and laser welding of retaining cables. The production process is very complex, investment costs are very high, and they have not been widely used. The workers cannot make the hairpin motor, because the workers don’t have enough physical strength to handle the thick metal wire and do a good job. Therefore, it costs a lot of money to buy a single line of hairpin motor assembly lines. For some car manufacturers, it may be best to invest in the production line of hairpin motors because the new car power industry has great potential for use. Each operation is performed with great precision and speed, given complete control of all stages of the production process. These machines offer the highest flexibility, reliability, and user-friendliness, serving as a powerful point to provide customized solutions, aimed at satisfying customer-specific or more complex needs around the world.

Future Development

To compete in the marketplace, it’s important to gamble on the technological innovations of motor-traction motors, which must be more integrated, brighter, with higher performance and lower feed. According to a recent study, the future development of the hair industry is divided into three categories.

- Phase One: 2018 to 2020, the entry level estimates that this motor hairpin will achieve a 50 percent penetration in annual sales of new high-powered cars.

- Phase Two: 2021-2022, the entry level assumes that this motor hairpin will achieve 90% penetration in the annual sales of passenger car drive motors.

- Third phase: After 2023, the market share will be close to 100%, and at the same time, it will gradually enter the consumer and passenger car sector, and the market share will continue to rise.

From the above, we can conclude that the automotive market is based on three factors: one with its past technology and production rain, one with more accurate forecasts of future trends, and the last one with a determination to lead the industry in performance.

The impact of introducing more layers on copper loss is considered, and the following conclusions are drawn.

- Using a high number of rotating layers does not always lead to low copper losses.

- Losses under different operating points should be considered while designing.

The development of new energy automobiles is an important way to address climate change and promote green development. Changes in global technology and industrial change have taken place in full swing, and technology related to the automotive and energy sector and transportation is accelerating day by day and has become a means of advancing in the automotive industry.

New power automobiles incorporate new power, new innovative ways and technology that is more flexible. In recent years, global automotive power has strengthened strategic planning and policy support. Global car companies have increased investment and improved the industry. These automobiles have become a major driver of change and development in the global automotive industry.

Honest Automation has developed the entire new energy hairpin motor stator assembly line, with mature hairpin winding technology. The advantages of the equipment include high speed, high reliability, high stability and intelligence.