There are a number of ways to treat and evaluate H₂S in the oilfield, and all have their pros and cons. This article offers an overview of the various methods, including treatment methods for liquefied H₂S, solid sorbent technology, hygroscopic materials, and others. This article discusses how H₂S is being used in the field, and the vast difference in the practical application of H₂S between oil drilling operations. In the oil industry, hydro-static testing and pressure testing are critical to maintaining safe production. This article provides detailed information on how H₂S is used in a variety of industries and how it is best evaluated during an evaluation.

Introduction

High-pressure hydraulics are usually used to increase the production of oil and natural gas wells, but they can also be applied in the recovery of oilfield fluids. These fluids may contain hydrogen sulfide, a colorless and flammable gas that comes from a variety of sources, such as bacteria and crude oil deposits. Hydraulic fracturing is typically performed at high pressures (~3000 psi) to release natural gas reserves within the rock formations surrounding an oil or gas well. The objective is not only to release the natural gas, but also reduce or eliminate the pressure gradient across the rock formation by injecting fluid into the wellbore. In order to process the hydrogen sulfide, there are a variety of methods that can be used. Some of these methods include the use of iron sponge h2s removal, molecular sieves and membrane filters.

What is H₂S?

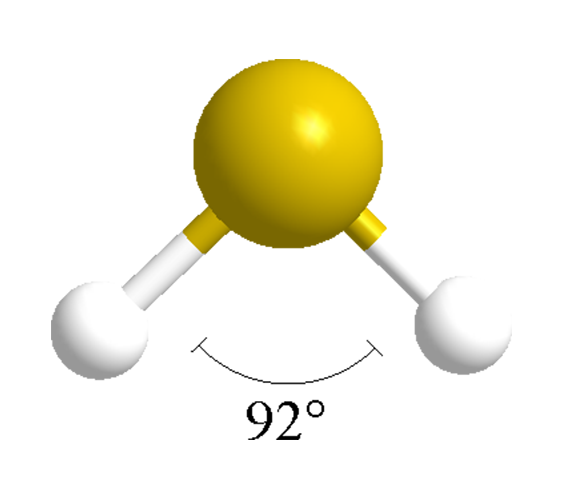

H₂S is a hazardous chemical that is used in oil production. It creates a toxic gas when mixed with air and water. The gas has no odor and has the potential to cause serious health problems such as dizziness, breathing problems, brain damage, and death in humans. H₂S, or hydrogen sulfide, is a naturally occurring gas with no color, taste or odor. It is produced in oil and natural gas wells due to chemical reactions that break down organic matter in the ground. H₂S is commonly called “bad air”. It can also be found in coal mines following explosions or chemical spills because it is heavier than air and moves closer to the ground.

What is the effect of H₂S in oilfield?

H₂S is a naturally occurring and very dangerous gas that is released from the ground when oil and natural gas are extracted. It can cause damage to the skin, eyes, lungs, as well as alter the nervous system. The effects of H₂S in oilfields can range from minor to fatal depending on what people are exposed to. H₂S is a reservoir fluid like oil, natural gas, or brine. When this fluid is exposed to the environment, contaminates like metals or hydrogen sulfide may be introduced into the air by condensation. Some of the effects of this exposure include an increase in levels of sulfur dioxide which can lead to acute respiratory distress and pulmonary edema.

How can the oilfield industries decrease the risks associated with H₂S?

There are many methods a company can use to decrease the risks associated with H₂S. The most effective method is to have a comprehensive H₂S risk management plan. This plan identifies a company’s specific needs and goals, and then evaluates the risks through different methods of treatment. The field industry workers are exposed to many risks, including H₂S exposure. This can lead to symptoms of infection and the development of severe conditions such as Guillain-Barré syndrome or myelitis. There are measures that can be taken to decrease the risks associated with H₂S exposure, including administering treatments such as corticosteroids or antibiotics, performing thorough personal protective equipment inspections, and providing training on how to protect against H₂S exposure.

Why are there so many H₂S scavengers available?

Once the oil field is created, there are a variety of H₂S scavengers that are used to collect, transport and treat the H₂S that is released. These devices include sorbents, collectors, scrubbers, filters and separators. There are a number of reasons why the oil and gas industry has placed so much attention on H₂S. There is an intense focus because it is an important environmental concern, but there are also economic benefits. The H₂S scavengers allow companies to remove H₂S in compliance with the U.S. EPA regulations and other international guidelines that affect the industry.

Specifics of a liquid phase H₂S scavenger

The most common H₂S scavenger is a liquid phase H₂S scavenger, which is an organic compound that forms spontaneously in hydrocarbons.

The specific liquid phase H₂S scavenger used by the industry is 1-butyl-3-methylimidazolium bromide, which is referred to as “BMI”. A particular liquid phase H₂S scavenger, which can be deposited in a reservoir, has recently been developed. It is a compound that effectively reacts with H₂S gas even at low concentrations and neutralizes it in water. This technology has the potential to alleviate the stress from oil field operators and diminish their risk of exposure to this toxic agent.

Discussing sorbents and related technologies

Oilfield operators are always looking for new technologies that can increase the productivity of their operations and help them reduce the environmental impact of their work. One of these technologies is sorbing agents designed to remove oil, gas, sand, and other materials from fluids. H₂S treatment and evaluation in the oil field are two common applications for sorbents, which are typically toxic in nature and need to be treated accordingly. “Sorbents are a type of material used to immobilize and capture hydrocarbons, typically oil and water. They are classified into two types; the more common non-woven sorbent and a woven mesh. The most common application of the sorbent is at wellheads.”

Conclusions

H₂S Treatment and Evaluation in the Oil Field is a project that looks at how to treat, transport, and monitor for the presence of H₂S during the extraction process of oil. H₂S is a life-threatening and disabling illness caused by the inhalation of hydrogen sulfide, which is present in oilfield fluids and can be hazardous when released into the air. HCs are important for their role as biological particles that provide nutrients to cells, and they also play a key role in gas exchange. With the increased use of H₂S as an artificial gas in metal degassing applications and natural gas handling at well sites, there has been a significant increase in reported cases.

Explain in

H₂S is the acronym for hydrogen sulfide, which is a naturally occurring gas that is often associated with sulfites and sulfur. It can be found in crude oil, natural gas reservoirs, and seeps. H₂S poisoning manifests many symptoms, including headache or dizziness, shortness of breath and chest pain, nausea and vomiting, profuse sweating, burning sensation in the throat and nose, confusion or disorientation.