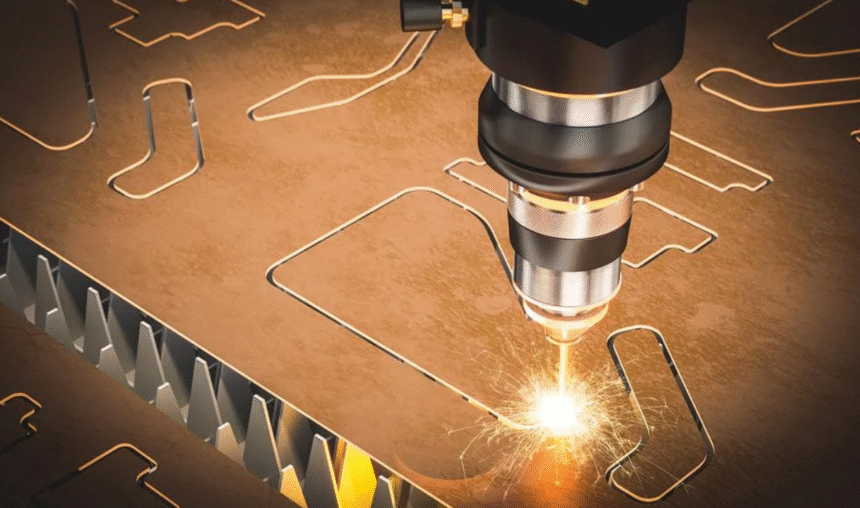

Considering investing in a fiber laser cutting machine? These machines are presently more popular than ever since they offer clean, fast, and precise cutting. Businesses across numerous industries depend on them to improve output and speed up production. Since these machines cost a lot, you need to make the right choice. Knowing the vital features before buying will assist you avoid costly mistakes.

7 Things To Know Before Buying A Fiber Laser Cutter

Buying a fiber laser cutting machine is a big step for any business. Here are seven key things to consider first.

1. Choose the Right Material

Not all fiber laser cutting machines handle materials the same way. A few work way better with carbon steel or stainless steel, whereas others are more effective on aluminum, brass, or reflective metals like gold and silver. Thicker or shinier surfaces may require higher-powered lasers or diverse laser sources. Understanding what materials you cut most often helps you avoid performance issues. Matching your machine to your material ensures clean results and longer machine life without unnecessary strain or modifications.

2. Consider the required Cutting Thickness

Each fiber laser cutter encompasses a limit for how thick it can cut, which depends on the laser’s control. Trying to cut beyond this restrain can lead to poor-quality edges or indeed harm the machine. It’s important to choose a model that aligns with your regular material thickness. Knowing this in advance helps you avoid delays and saves repair costs. A well-matched machine gives you smoother, more consistent results without overloading the system or slowing down your workflow.

3. Evaluate Power and Precision

Laser power affects both the speed and depth of your cuts. If you work with thick metals or want to complete jobs faster, go for a higher-wattage machine. Precision is just as important, especially if you’re in industries like aerospace or electronics. These fields need clean, sharp edges with very small margins for error. Hence, choose a machine that offers excellent precision and stable performance. Make sure you match the power level and accuracy of your job type so that your work stays efficient and professional.

4. Focus on Cutting Speed and Productivity

Speed is one of the major advantages of fiber laser cutting. These machines work up to three times faster than conventional strategies like CO2 or plasma cutters. Faster cutting boosts productivity without sacrificing quality. Whether you handle large orders or need to meet tight deadlines, speed can improve delivery times and lower labor costs. A fast, reliable cutter keeps your projects moving and helps your business grow. Make sure the machine you choose meets your production needs from the start.

5. Plan Space and Layout

Measure the space you have in your shop or production floor before buying a fiber laser cutting machine. These machines are regularly compact but still require room for loading materials, ventilation, and secure movement. Consider how people will work around it and where the finished parts will go. Proper planning prevents crowded or unsafe setups. A smart layout helps your team stay efficient and reduces the risk of accidents. Choose a machine size that fits your workspace and supports smooth daily operations.

6. Budget and Operating Costs

Buying a fiber laser cutter is a big venture, but it’s also a cost-saving device over time. These machines usually have low maintenance needs, utilize less power, and last for a long time. You’ll also save on things like replacement parts and consumables. Rather than focusing only on the upfront cost, consider how much you’ll spend or spare in the long run. A well-chosen machine can cut costs, decrease downtime, and provide solid performance for a long period of time.

7. Safety and Support

Laser cutters are strong tools that require careful handling. Always think about ventilation, enclosures, and clear safety zones. It’s important to train everyone who operates the machine. Look for brands that offer solid support, including setup help and maintenance tips. Good customer service ensures you can fix problems quickly and avoid delays. When your team knows how to use the machine safely, you reduce risks and improve performance. Support and safety together make a big difference in day-to-day operations.

Conclusion

Think about your material types, cutting thickness, control, speed, space, budget, and safety before buying a fiber laser cutting machine. Each of these variables plays a huge role in the machine’s performance and your daily workflow. A smart choice today can lead to better results and fewer issues in the future. Trusted manufacturers like Cesar CNC can help guide you through the process, offering machines that match your needs and end goals. Take the time to plan carefully, so you’ll be able to invest in a solution that genuinely supports your business.