Did you know that William Haviland Carrier invented the first practical air-conditioning system on July 17, 1902? This ignited an industry that would transform the way we live and work for the rest of our lives! This has progressed to use in every electronic technology that requires effective cooling for their panels.

Modern electrics are highly susceptible to heat and contamination. High temperatures cause component failure, digital display malfunction, control drift, and breaker failure. Because of this, machine or industrial manufacturing line failures can result in lost production.

Do you want to know if an electronic panel cooler is worthwhile? Learn why it’s critical to keep electronics and electronic panels cool here.

Why Do You Need to Cool an Electronic Panel?

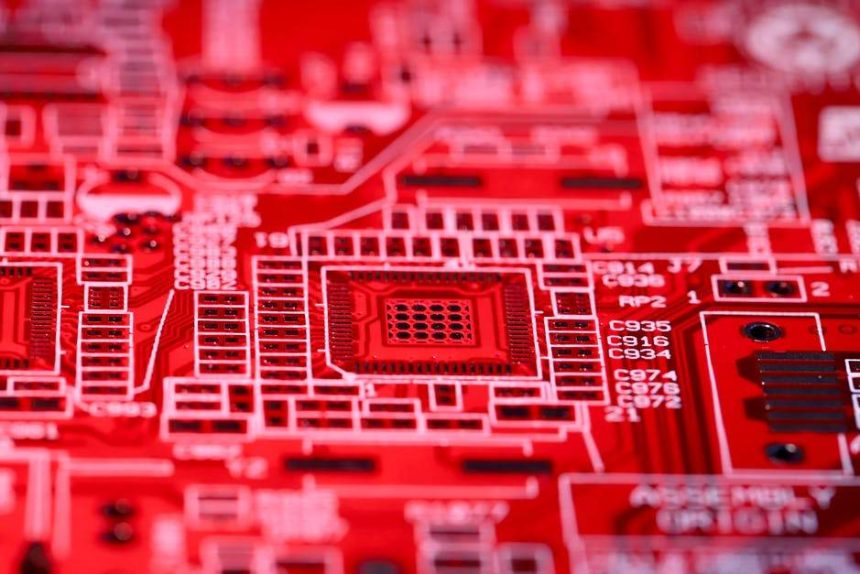

Electronic panels and other enclosures include sensitive components that create heat during operation. This heat can build up inside the enclosures, forming dangerous heat spots.

The heat created by electrical panels has the possibility to trigger malfunctions and failures. The components that could be affected are usually housed within:

- Computer server racks

- Electrical enclosures

- Other product compartments

Thus, effective control panel cooling solutions are critical to any business’s performance. The efficiency of the cooling system chosen may have a significant impact on the overall success of its operations.

The Different Applications for Cooling Management

Even in normal working conditions, electrical control panels may be used for a wide range of applications.

Heat can cause an enclosure’s interior temperature to surpass the manufacturer’s standards. Listed below are two of the heat sources.

Internal Heat Sources such as computers and electronic components generate a certain amount of heat. These include:

- Power supplies

- Switches and routers

- Servers

- Power supplies

- Drives and Inverters

- PLC systems

The surroundings in which an enclosure is placed might also contribute to undesirable heat buildup. These include:

- Engine Rooms

- Industrial ovens

- Manufacturing plants

- Foundries

- Food processing factories

- Climate

This means that companies that use a range of technologies will benefit from adopting cooling management systems that are easily adaptable to individual needs. Read more here!

Cooling Solutions

There are various solutions to help with heating problems. These include:

- Filtered ventilation

- Localized ventilation used in enclosure coolers such as fans

- Cooling or thermoelectric units such as vortex coolers

- Other mechanical temperature and humidity regulators

All these maintain optimal operability levels. They can all interact using filter fans, heaters, and cooling units.

Keep Your Electronics Cool!

Electronic panel coolers are a great way to keep enclosures, electrical panels, and cabinets cool.

As technology advances, more and more sensitive electronics are being housed in smaller and smaller containers. This increases the risk of overheating. Cabinet coolers provide a solution to these issues by cooling and circulating clean air within the cabinet while maintaining the enclosure’s protective barrier against impurities such as dust, oil, or dirt.

Has this article given you a better insight as to why it’s important to keep electronic panels cool? Then, why not browse our page for more interesting and exciting articles from politics to sports, to business and finance!