Picture this: you’re managing a bustling manufacturing facility. Systems are humming, temperatures are finely controlled, and production lines are firing on all cylinders. But then, something disrupts the balance. Maybe it’s a refrigerant system needing servicing or an unexpected equipment failure. When that happens, there’s one tool production engineers know they can count on to save both time and resources: a mobile evacuation system.

- What Are Mobile Evacuation Systems and Why Do They Matter?

- Challenges in Refrigerant Recovery Without Mobile Solutions

- How Mobile Evacuation Systems Simplify Production Processes

- Why Your Facility Needs a Mobile Evacuation System

- Tips for Integrating a Mobile Evacuation System in Your Workflow

- Future-Proofing Your Facility with Mobile Solutions

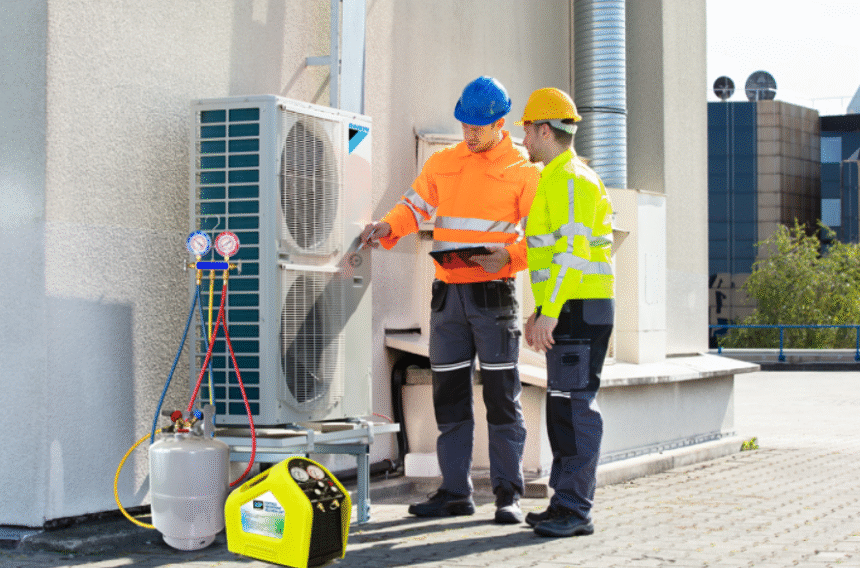

Refrigerant recovery during maintenance or repairs is no trivial task. Without the proper tools, it can be messy, complicated, and even environmentally harmful. That’s where a mobile evacuation system steps in, making the recovery process cleaner, faster, and much more efficient. If you’re new to these systems or want to discover how they can make your life easier, this is the blog for you.

What Are Mobile Evacuation Systems and Why Do They Matter?

At its core, a mobile evacuation system is a versatile solution designed to recover refrigerants during system maintenance or production interruptions. Unlike static systems, these mobile units are, as the name suggests, portable. They bring flexibility and convenience to intricate processes, especially in large facilities with multiple systems spread across different areas.

These systems aren’t just about convenience, though. They play an important role in:

- Reducing Downtime: By allowing engineers to quickly move recovery tools to where they’re needed.

- Protecting the Environment: Proper refrigerant recovery reduces harmful emissions and ensures compliance with environmental regulations.

- Improving Efficiency: Mobile systems eliminate the hassle of moving heavy equipment to perform the job.

Challenges in Refrigerant Recovery Without Mobile Solutions

If you’ve been in the production world long enough, you know that refrigerant recovery isn’t always smooth sailing. Without a mobile evacuation system in place, a few common headaches may arise:

- Stationary Limits:

Static systems require the equipment to come to them. But in a busy production facility, you don’t have the luxury of unhooking and transporting machinery just to recover refrigerants.

- Time-Consuming Setup:

Traditional systems often involve cumbersome logistics, wasted labor hours, and excessive downtime to set up and break down.

- Safety Concerns:

Handling refrigerants improperly in industrial scenarios can lead to leaks, spills, or exposure to harmful chemicals, not to mention the environmental implications.

Imagine trying to transport bulky recovery equipment to a remote corner of your facility just because the system there requires servicing. It’s not fun, and it’s definitely not efficient. Any production engineer who’s faced this scenario knows the value of a more flexible alternative.

How Mobile Evacuation Systems Simplify Production Processes

Here’s how mobile evacuation systems act as a game-changer in refrigerant recovery workflows:

1. Portability Brings Flexibility

Mobility is the name of the game. With these systems, you can easily bring recovery processes to the exact spot where they are needed. No more hauling production equipment across the facility to access a stationary evacuation setup. You save time, effort, and minimize disruption.

2. Compact Design for Tight Spaces

Manufacturing facilities often come with cramped areas and tricky layouts. Mobile evacuation systems are designed to maneuver through tight spots, allowing recovery to take place even in challenging areas. Imagine the relief of not needing a forklift to move bulky setups into a back corner!

3. Streamlined Workflow

Many mobile systems are built to work seamlessly with existing production setups. This compatibility reduces the time spent fiddling with additional adapters or setups. Instead, they integrate quickly and move on to getting the job done.

4. Eco-Friendly Compliance

Most modern mobile evacuation systems come equipped with features that ensure compliance with stringent environmental regulations. This means you’re not only safeguarding your workplace and workers but also reducing the environmental footprint of your operations. It’s a win-win.

Why Your Facility Needs a Mobile Evacuation System

Still on the fence about investing in a mobile evacuation system? Here’s a quick rundown of the benefits tailored to production setups like yours:

- Efficiency: Shift from hours of recovery work to just minutes.

- Cost-Effectiveness: Minimize downtime while keeping productivity high.

- Safety: Protect your team by ensuring safe and secure refrigerant handling.

- Versatility: These systems can handle a variety of refrigerant types, making them well-suited for diverse facilities with different equipment needs.

- Sustainability: Help meet your facility’s green goals by recovering refrigerants responsibly.

Tips for Integrating a Mobile Evacuation System in Your Workflow

Successfully adding a mobile evacuation system to your facility’s operations isn’t just about hitting “buy” on new equipment; it’s about ensuring the transition improves performance without hiccups. Here are a few tips:

- Train Your Team:

Even the best technology falls short in the hands of an untrained team. Invest in training sessions to show your staff how to safely and effectively use the mobile system.

- Start Small:

If you’re unsure, start with one portable unit to gauge its effectiveness. Once its benefits speak for themselves, it’ll be easier to justify scaling up.

- Ensure Compatibility:

Check that the system you choose is compatible with the refrigerants and production setups you currently use.

- Maintenance Is Key:

Just because it’s cutting-edge doesn’t mean it’s maintenance-free. Regularly check your mobile evacuation system to ensure it remains reliable over time.

Future-Proofing Your Facility with Mobile Solutions

As production environments evolve, so too do the tools and technology designed to support them. Mobile evacuation systems are rapidly becoming a must-have solution for facilities that value flexibility, efficiency, and sustainability. Beyond just saving time and effort during refrigerant recovery processes, they’re enabling production engineers to focus on what truly matters—keeping operations running smoothly.

If you’ve been putting off upgrading your recovery processes, the time to act is now. Invest in a mobile evacuation system and streamline your facility’s operations while staying ahead of industry trends.