Cold storage is a critical component of many industries, from food and beverage to pharmaceuticals. The ability to maintain specific temperatures can mean the difference between a successful operation and a costly failure. Unfortunately, cold storage failures are not uncommon, and the repercussions can be severe. Understanding the lessons learned from these failures can help businesses implement better practices and avoid similar pitfalls.

The Importance of Reliable Cold Storage

Cold storage systems are designed to preserve perishable goods, ensuring they remain safe for consumption or use. However, when these systems fail, the consequences can be dire. For instance, a malfunctioning refrigeration unit can lead to spoilage, waste, and financial loss. In some cases, it can even result in health risks for consumers.

To mitigate these risks, businesses must have contingency plans in place. This is where emergency storage options come into play. Having access to backup cold storage solutions can be a lifesaver during unexpected equipment failures. For example, companies can rent portable cold storage units to maintain the integrity of their products while repairs are underway. This proactive approach not only protects inventory but also safeguards a company’s reputation.

Common Causes of Cold Storage Failures

Understanding the root causes of cold storage failures is essential for prevention. Here are some of the most common issues:

1. Equipment Malfunction

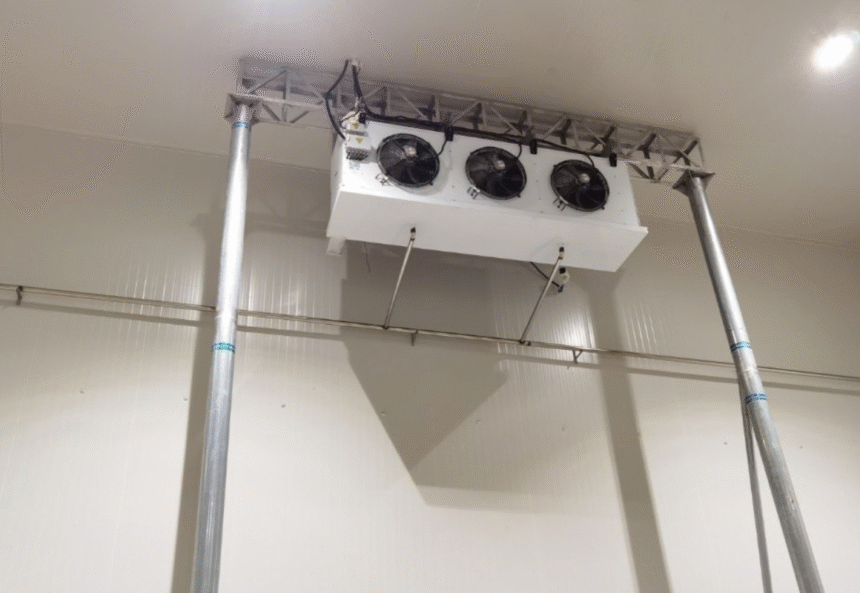

Refrigeration units, like any machinery, can fail. Whether due to wear and tear, lack of maintenance, or manufacturing defects, equipment malfunctions can lead to temperature fluctuations. Regular maintenance checks and prompt repairs are crucial to keeping systems running smoothly.

2. Power Outages

Power outages can disrupt cold storage operations, leading to temperature rises that can spoil goods. Businesses should consider investing in backup power solutions, such as generators, to ensure continuity during outages. Additionally, monitoring systems that alert staff to temperature changes can help mitigate risks.

3. Human Error

Human error is another significant factor in cold storage failures. This can range from improper loading of goods to neglecting to monitor temperature settings. Training staff on best practices and implementing standard operating procedures can help reduce the likelihood of mistakes.

4. Poor Insulation

Insufficient insulation can lead to energy inefficiencies and temperature inconsistencies. Ensuring that cold storage facilities are well-insulated can help maintain stable temperatures and reduce energy costs. Regular inspections can identify areas needing improvement.

Lessons Learned from Cold Storage Failures

The failures of cold storage systems provide valuable lessons that can be applied across industries. Here are some key takeaways:

1. Invest in Quality Equipment

Choosing high-quality refrigeration units and storage solutions is essential. While it may be tempting to opt for cheaper options, investing in reliable equipment can save money in the long run by reducing the risk of failures.

2. Implement Regular Maintenance

Establishing a routine maintenance schedule can help identify potential issues before they escalate. Regular checks should include cleaning coils, checking seals, and ensuring that temperature monitoring systems are functioning correctly.

3. Train Staff Thoroughly

Staff training is vital in preventing human error. Employees should be well-versed in the operation of cold storage systems, including how to respond to alarms and temperature fluctuations. Regular training sessions can reinforce best practices and keep staff informed about any updates or changes.

4. Develop Contingency Plans

Having a contingency plan in place is crucial for any business relying on cold storage. This includes knowing who to contact for repairs, having emergency storage options available, and ensuring that staff are trained to implement the plan effectively.

5. Monitor and Adapt

Continuous monitoring of cold storage conditions can help identify trends and potential issues. By analysing data from temperature logs and equipment performance, businesses can adapt their practices to improve efficiency and reduce the risk of failures.

The Role of Technology in Cold Storage Management

Advancements in technology have significantly improved cold storage management. Smart sensors and IoT devices can provide real-time monitoring of temperature and humidity levels, alerting staff to any deviations. This proactive approach allows for immediate action, reducing the risk of spoilage.

Additionally, data analytics can help businesses identify patterns and make informed decisions about their cold storage practices. By leveraging technology, companies can enhance their operational efficiency and safeguard their products.

Conclusion

Cold storage failures can have serious consequences, but by learning from past mistakes, businesses can implement strategies to prevent them. Investing in quality equipment, maintaining regular checks, training staff, and developing contingency plans are all essential steps in safeguarding cold storage operations.

As industries continue to evolve, the importance of reliable cold storage will only grow. By prioritising these lessons and embracing technological advancements, businesses can ensure that their cold storage systems remain efficient and effective, ultimately protecting their products and their bottom line.