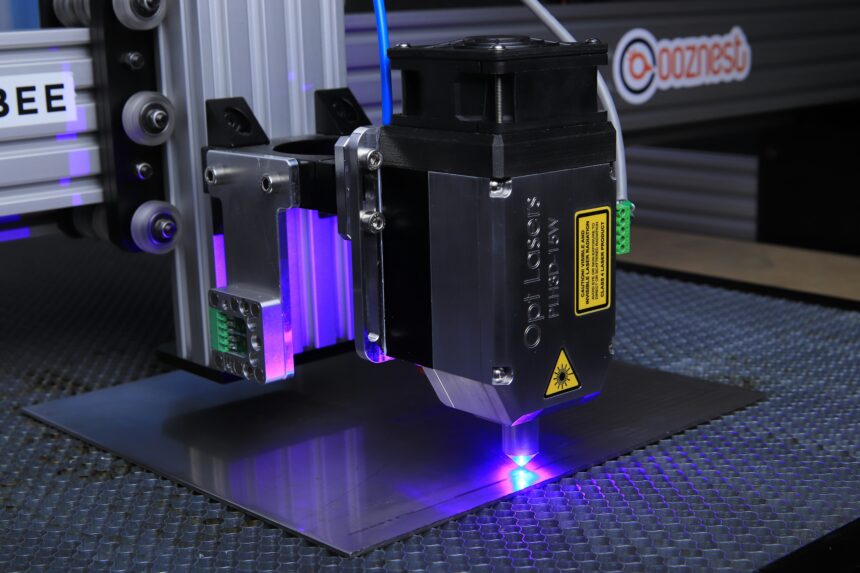

Laser technology has seen significant adoption across various industries due to its multitasking capabilities. This multitasking capability has led to improved efficiency, reduced production time, and enhanced product quality.

The global laser technology market was valued at USD 17.82 billion in 2022. It is projected to expand at a 7.8% CAGR, driven by versatile applications across industries like healthcare, automotive, and defense. With advances in 3D laser technology and innovations such as VCSEL for data transfer, demand continues to rise.

In this article, we’ll explore how laser processing shapes innovation, boosts production, and paves the way for more sustainable manufacturing practices.

Enhancing Precision and Accuracy

According to ScienceDirect, laser-based hybrid micromachining processes (LHMMP) enhance precision by integrating laser beam machining with conventional and non-conventional methods. This method effectively addresses issues like thermal stresses and burrs, improving surface quality and efficiency through external energy sources integration.

Guided by advanced software systems, lasers allow manufacturers to make detailed cuts and engravings with minimal variation or error. This is especially crucial in fields such as medical device manufacturing, electronics, and aerospace, where extremely tight tolerances are required.

Unlike traditional methods, laser processing does not suffer from tool wear, ensuring more consistent and repeatable results. It also accommodates a wide range of materials, including metals, plastics, and ceramics.

What are the tolerances achievable with laser cutting compared to mechanical cutting?

Laser cutting achieves much tighter tolerances than mechanical cutting, often as precise as ±0.003 inches, while mechanical methods typically offer tolerances around ±0.010 inches or higher. The non-contact nature of laser technology prevents tool wear, resulting in cleaner edges and greater consistency.

Increasing Production Efficiency

Traditional manufacturing methods often involve multiple steps, such as machining, cutting, and assembly, making them time-consuming and resource-intensive. In contrast, laser processing streamlines these workflows by providing rapid and precise cutting, welding, and marking in a single operation.

As a non-contact method, lasers eliminate the need for frequent tool replacements and maintenance typically required by mechanical processes. They can efficiently process various materials, allowing manufacturers to quickly switch between tasks and reducing the number of machines needed.

One of the primary advantages of laser processing is its remarkable speed. Lasers can operate at high speeds without sacrificing accuracy, enabling manufacturers to produce parts more rapidly than with conventional methods. This acceleration results in shorter lead times, allowing companies to respond more effectively to market demands and customer needs.

According to Novanta Photonics, ultrafast laser development has gained significant momentum over the past thirty years, generating widespread interest and advancements. Researchers and system designers have developed various techniques to generate ultrashort laser pulses, increasing the accessibility of ultrafast lasers in manufacturing.

Reducing Waste and Material Costs

According to NCBI, additive manufacturing (AM) reduces material waste and eliminates tooling, lowering costs and emissions by up to 45%. The geometric freedom of AM enables on-site production, customization, and design changes, cutting tooling costs that account for 80% of traditional manufacturing. The environmental and economic advantages align perfectly.

Its precision allows for cutting with minimal material loss, significantly improving over traditional mechanical processes that often generate excess waste. By making cleaner cuts and more accurate engravings, laser technology enables manufacturers to maximize material utilization.

This aspect is crucial when using expensive materials, such as metals or composites, where minimizing waste can lead to cost savings. Lasers eliminate the need for consumable materials, like blades or cutting fluids, further reducing operational costs.

Enabling Complex Designs and Customization

Laser processing enables manufacturers to create highly complex designs and customized products with detail levels that are challenging to achieve using traditional methods. The precision of lasers enables intricate patterns and fine geometries, especially valuable in industries like aerospace, automotive, and electronics.

Laser systems are flexible and can process a wide range of materials and thicknesses, enhancing adaptability in design. Whether manufacturers are prototyping or creating bespoke products, laser processing supports faster iteration and greater design freedom.

Can laser processing be used for rapid prototyping in additive manufacturing?

Yes, laser processing is commonly used for rapid prototyping in additive manufacturing. It enables fast, accurate cutting and layering of materials, essential for creating detailed prototypes. Technologies like laser sintering facilitate quick transformations from digital designs to physical models, supporting iterative development and accelerating product market entry.

Supporting Lightweight Materials

Laser processing is essential for working with lightweight materials, which are increasingly demanded in industries such as aerospace and automotive. These materials, including aluminum, carbon fiber, and titanium, often require high-precision cutting and joining to maintain their structural integrity.

Laser technology’s non-contact processing makes it ideal for delicate and lightweight components, reducing the risk of deformation and damage. Lasers can produce thinner and more precise cuts, enabling manufacturers to create lighter products without sacrificing strength.

Driving Sustainability in Manufacturing

Laser processing is advancing sustainability in the manufacturing industry by improving energy efficiency, reducing waste, and eliminating harmful byproducts. Traditional manufacturing methods often require consumables like cutting fluids or physical tools, which generate waste and use more energy.

In contrast, laser systems operate without physical contact, reducing the need for consumables and lowering energy consumption. Fiber lasers, in particular, are known for their energy efficiency, consuming less power while delivering high precision. Lasers generate less material waste by making cleaner cuts, which minimizes excess scrap and optimizes resource use.

Springer Nature states laser processing enhances sustainability by optimizing energy efficiency through Specific Energy Consumption (SEC) analysis. In one study, the energy usage for six products was tracked, revealing significant power variation across operating states. Processing state efficiency correlates inversely with SEC, and laser cutting reduces carbon emissions by 0.21016 kg CO2/kWh.

Are there specific laser technologies designed to further reduce energy consumption?

Yes, specific laser technologies like fiber lasers are designed to reduce energy consumption. Fiber lasers offer high energy efficiency, around 75%, compared to CO2 lasers’ 20%. This makes them ideal for industrial applications, where reducing power usage is crucial. They also require less maintenance and have lower operating costs, further optimizing energy consumption.

Laser Technology is Revolutionizing Manufacturing

Laser processing is transforming the manufacturing industry by offering advanced precision, efficiency, and sustainability. Its capability to support complex designs, reduce waste, and utilize lightweight materials makes it essential in industries such as aerospace, automotive, and electronics. Moreover, laser systems contribute to greener manufacturing practices by reducing energy consumption and waste.